New version of Fusion 360 model - I'll leave this up for a week or so if anyone wants to get a copy. After that, I may be making more modifications and will upload a new version once they are complete.

https://www.dropbox.com/s/65rxlmvho0us2 ... y.f3z?dl=0

All the fasteners are included in this one, along with a reorganization of some of the subassemblies to make it work better in Fusion 360.

Here's a preliminary list of alterations to the original I3-RS by Romain.

-----

Z Braces

Added 2nd Z Brace

Changed mounting brackets for Z brace at top and bottom – both sides

Changed from 8mm to 5/16-18 threaded rod for easier sourcing in Canada/US

Power Supply

Increased height of power supply bracket by 14mm - allows power supply to clear second lower Z brace

Raised power supply mounting bracket by 14 mm on frame to allow second z brace to be installed

Heavily modified power supply enclosure to allow a more balanced look on frame, along with the mounting tab to line up with power supply bracket used in extrusion. This altered the mounting hole locations on the main frame.

Frame

Modified frame pieces – main, front, back, heat bed support – to 6mm aluminum and waterjet/laser cut pieces

Aluminum Extrusions

Lengths changed to accommodate the 6mm thick frame component as opposed to the original 8mm.

Increased Rear Aluminum Extrusions to 98mm from 96mm to compensate for 6mm Main Frame

Heatbed

Heatbed has countersunk 3mm holes – modified mounting configuration from original that used M3/6-32 PC motherboard standoffs.

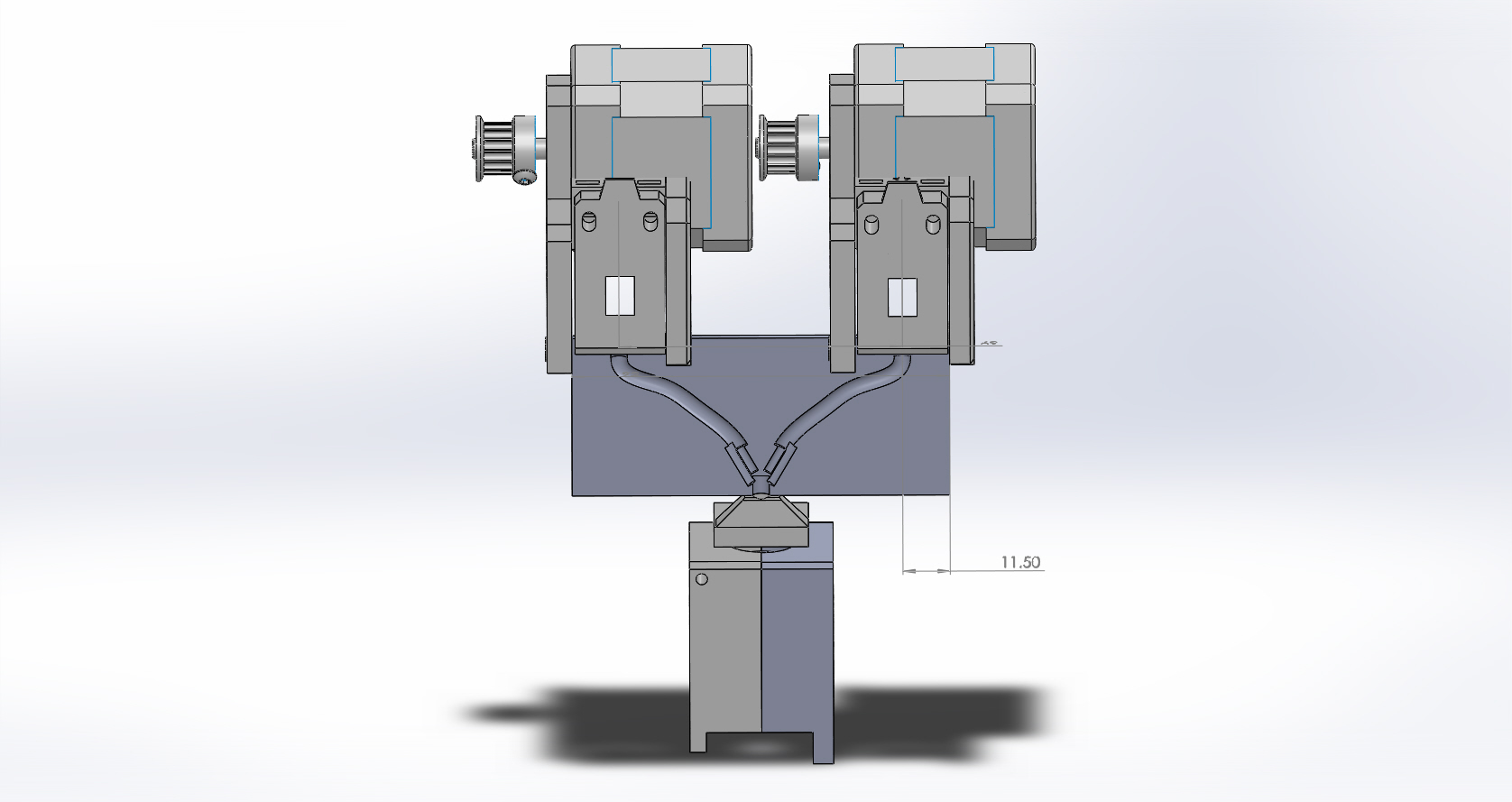

X/Y Carriage

Added small “bumps” to center pulley like in the Y axis pulley bracket

LED Bar

New led bar designed to use 1/8” x 3/4” aluminum flat bar available in Canada/US

Mounting hole spacing altered to accommodate the new Z Brackets

LM8UU Bearing Mounting Alterations

Made LM8UU Bearing Slots & Zip Tie Holes Symmetrical With Bed Support Layout

Original was slightly off for some unknown reason – traced back to Prusa design that I3-RS is based on. This resulted in bearings moving closer together by about 2mm.